Stainless Steel Ball Valve - Technical Specifications

Contents:

One Piece Ball Valves

Two Piece Ball Valves

Three Piece Ball Valves

Three Way Ball Valves

2000 PSI Ball Valves

Features:

- ● Suitable Mediums: Water, Oil and Gas type substances. (WOG)

- ● Seats & Seals: Teflon (PTFE)

- ● Threads: Female NPT (Female National Pipe Thread)

- ● Standard Port: Reduced Bore Ball Valve (ID is one size smaller than the pipe size)

- ● Handle: Blow-Out Proof

- ● Handle Locking Mechanism: handle equiped with locking device (Re-movable)

Performance Specifications:● Pressure Rating: 1000 PSI (6.4MPa) Making them suitable for most applications.

●Temperature: -13⁰F to 302⁰F (-25°C to 150°C)

● Shell Test: 9.6MPa

● Seat Test: 0.6MPa

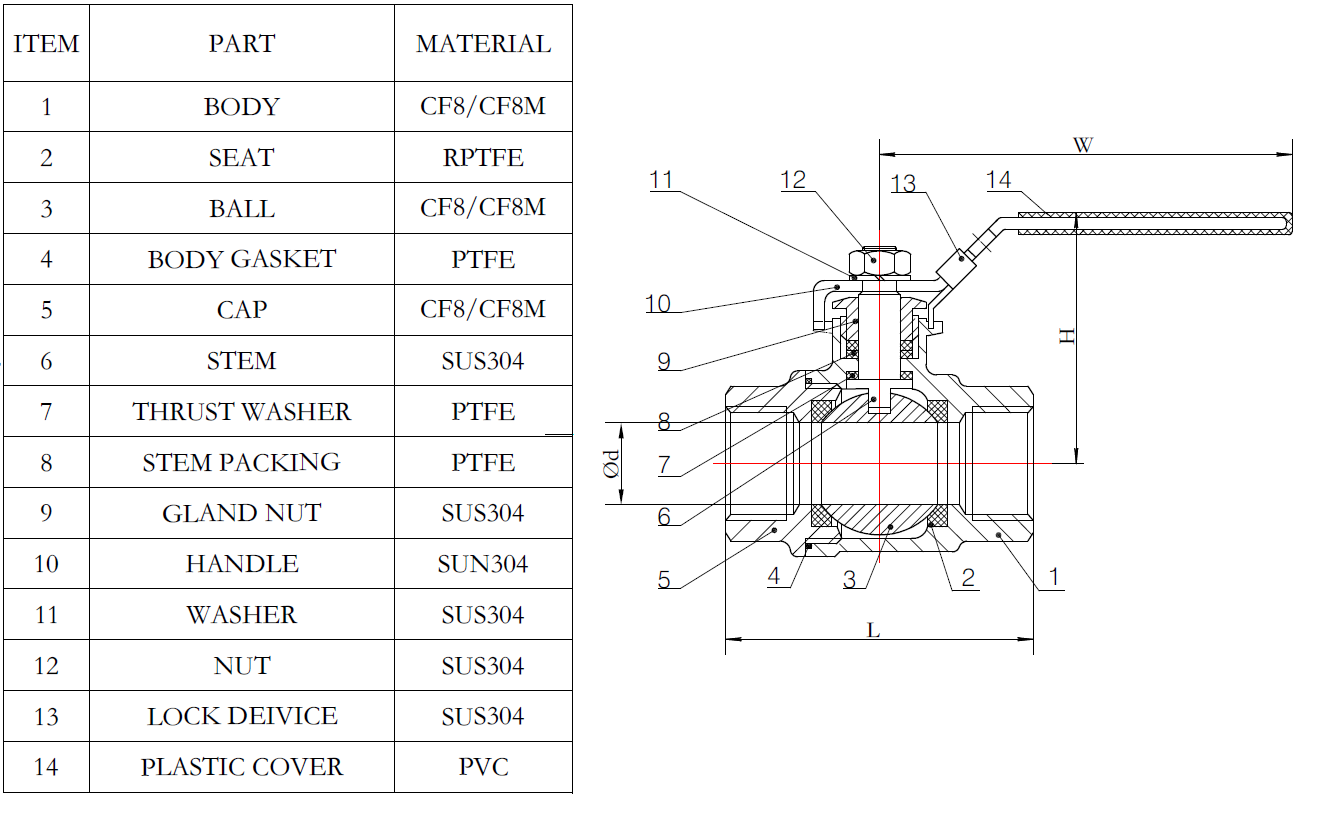

General Characteristics:

- ● These are the best priced ball valves due to the fact that the valve body is made out of one piece.

- ● The benefit of this is that there are no joints for leaking to occur making these 1 piece ball valve's durable and reliable.

- ● The down side of the one piece design is that this makes it a standard port ball valve, also called a reduced port.

- ● This means the ID of the pipe drops one size, once the valve is installed in line.

- ● No tooling is needed for installation.

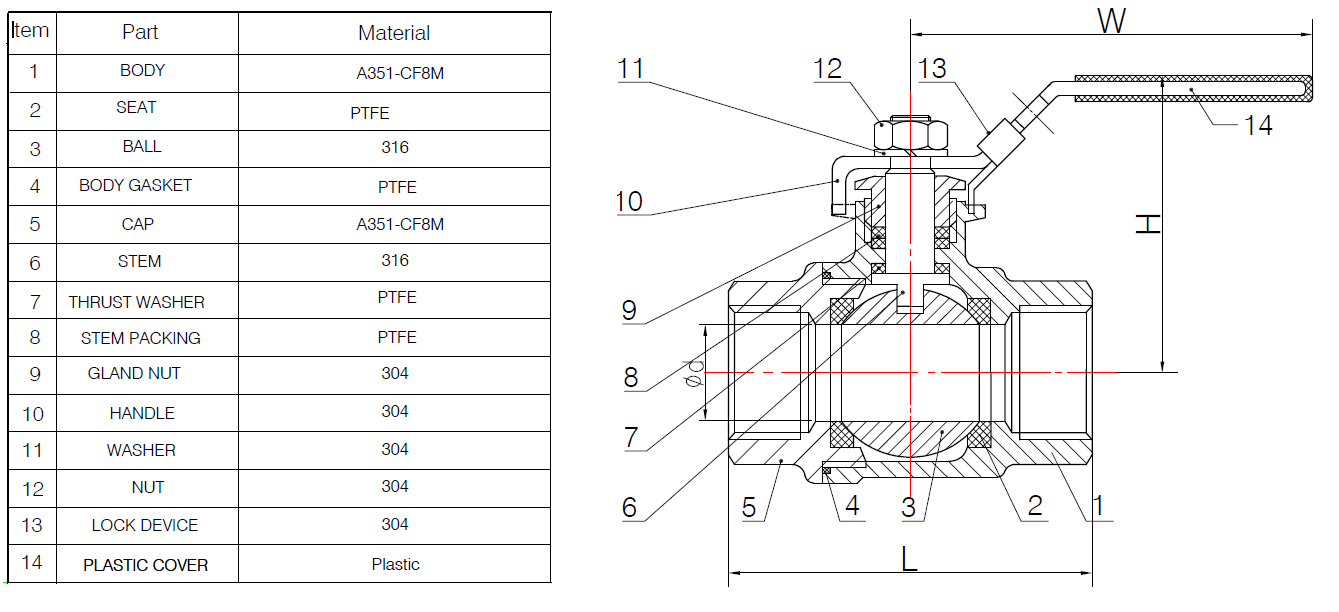

Material Components:

- ● Valve Body: is cast from Stainless Steel 316 (CF8M)

- ● Seals & Seats: are composed of Teflon (PTFE)

- ● Compatability: Compatible on all substances that are suitable for use with both Teflon and Stainless Steel 316

- ● All wetted Parts are 316 Stainless Steel. The rest of the valve that doesn't touch the transported Material is composed of 304 Stainless Steel.

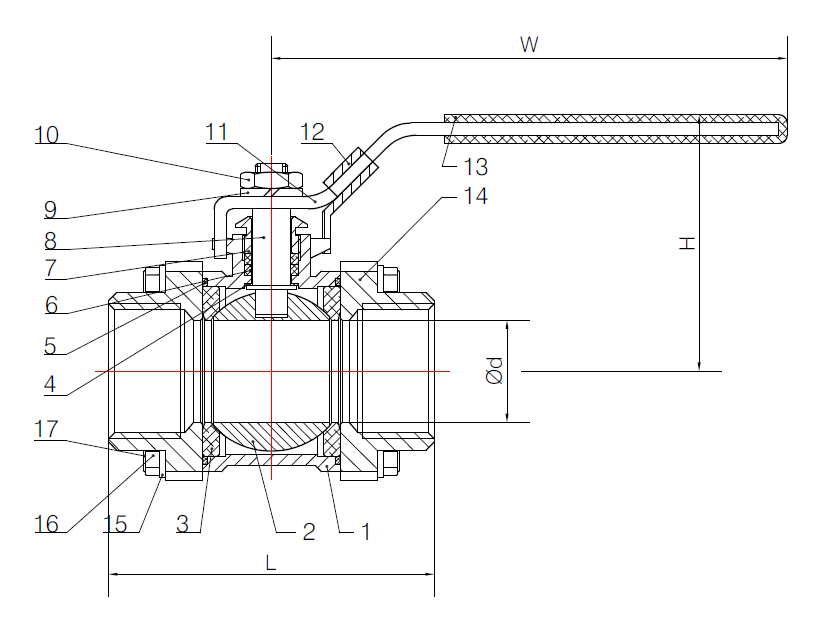

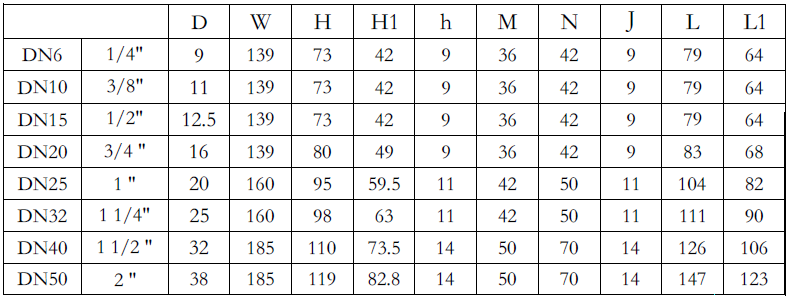

General Dimensions:

- ● The size of the ball valve required depends on the size of the thread. (1-1/2" Threads use 1-1/2" Ball Valves.)

- ● The body of valve is manufactured out of one piece, this means that a smaller ball is installed into this valve than can be fitted into the 2-Piece or 3-Piece options. Since The 2 & 3 Piece can be opened up to recieve a larger ball.

- ● The draw back is that this leads to a reduced port.

- ● While the advantage is the chance of leaking is reduced, since the body is one piece with no joints that could become leaking points!

● Pressure Chart:

Design Data:

- ● Casting: Investment Casting AD2000-WO

- ● Dimension standards: DIN3202/4-M3, din2999/259, ISO228-1,ISO7-1, ASME B1.20.1,BS21

- ● CE Approval: DN32~DN100

- ● Inspection & Testing: En12266-1,API 598

- Shell test pressure :95 bar for DN6~DN50; 60bar for DN65~DN100

- Shell Test Pressure: 95 Bar for DN6-DN50; 60 bar for DN65-DN00

- Seal Pressure Test: 70 bar for DN6-~DN50; 44bar for DN65~DN100

- Low Pressure Test : 6~8 bar

- ● Pressure at max. Temperature:44.5 bar for 1.4308 and pn63,50.2bar for 144.8 adn PN63; 28.2 bar for 1.4308 and PN40,31.8 bar for 1.4408 and PN40

- ● Pressure at min. Temperature: 59.7 bar for 1.4308 and PN63, 61.2 BAR FOR 1.4408 and PN63; 37.9 bar for1.4308 and PN40,38.8 bar for 1.4408 and PN40

- ● Corrosive Allowance : 2mm

- ● Design & Manufacture : According to EN12516-1/-2,PED97/23/EC (CE0036)

Click Here for the 1 Piece Stainless Steel Ball Valves Page

Features:

- ● Suitable Mediums: Water, Oil and Gas. (WOG)

- ● Seats & Seals: PTFE (Teflon)

- ● Threads: Female NPT (Female National Pipe Thread)

- ● Full Port: Full Bore Ball Valve (ID is remains the same size as the pipe)

- ● Handle: Blow-Out Proof

- ● Handle Locking Mechanism: handle equiped with locking device (Re-movable)

Performance Specifications:● Pressure Rating: 1000 PSI (6.4MPa) Making them suitable for most applications.

●Temperature: -13⁰F to 302⁰F (-25°C to 150°C)

● Shell Test: 9.6MPa

● Seat Test: 0.6MPa

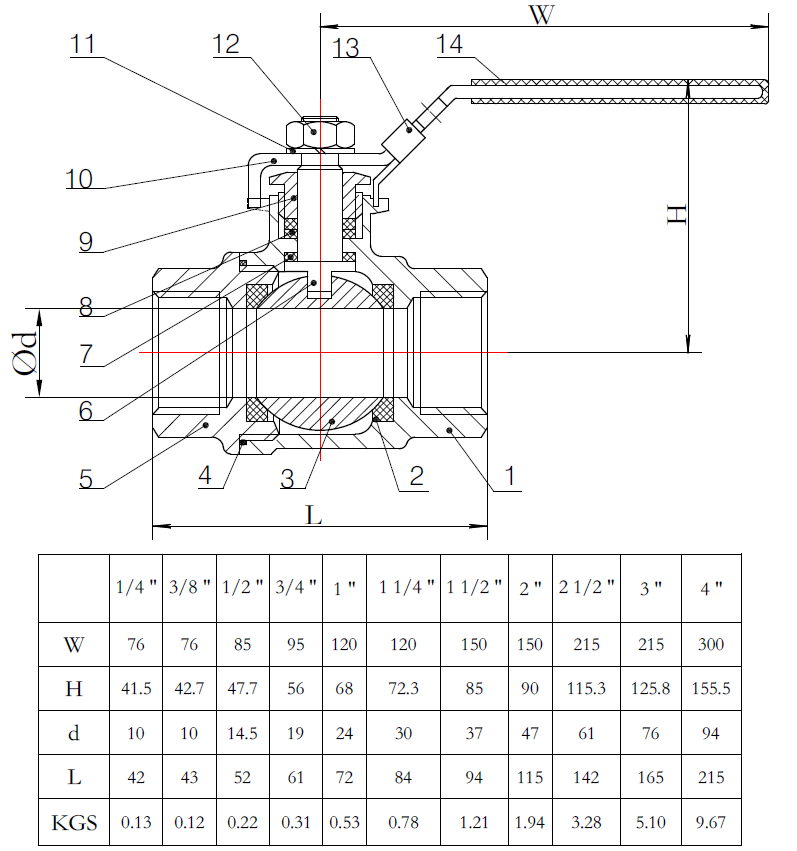

General Characteristics:

- ● Also called a two-way ball valve, since it allows flow straight through from both directions.

- ● The 2 piece ball valve is a full port valve, which means the ID of the pipe remains constant through out, once the valve is installed in line.

- ● These are the most widely used in all industries due to their low cost, ease of use and durability.

- ● No tooling is needed and they can thread directly onto the pipe.

Material components:

- ● Valve Body: is composed out of Stainless Steel 316 (CF8M)

- ● Seats & Seals: are made out of Teflon (PTFE)

- ● Compatability: Good for any substances that are compatible with Stainless Steel and Teflon (PTFE)

- ● Non-wetted parts that do not touch the material being transported are Stainless Steel 304.

General Dimensions:

- ● The size of the pipe determines the size of the ball valve required. ( 2" Pipe will need a 2" ball valve etc)

- ● These threaded ball valves require no tools to install. (The Female NPT of the valve will screw directly onto a Pipe with Male NPT )

- ● We stock two styles of 2-piece ball valves:

- -The Compact Style: Ideal for tight spaces or where budget is a concern.

- -The Heavy Duty Style: Slightly larger and heavier and has a larger handle.

- Compact Style (304 and 316)

- Heavy Duty Style (316)

● Pressure Chart:

Design Data:

- ● Casting: Investment Casting (AD2000-WO)

- ● Dimention Standards: According to DIN299/259; ISO228-1; JIS B0203; ISO7/1

- ● Threads: ASME B1.20.1 BS21 DIN299/259

- ● Approvals: CE0035

- ● Inspections and Testing: Acording to EN12266-1, API 598

Click Here for the 2 Piece Stainless Steel Ball Valves Page

Features:

- ● Suitable Mediums: Water, Oil and Gas. (WOG)

- ● Seats & Seals: Teflon (PTFE)

- ● Threads: Female NPT (National Pipe Thread)

- ● Full Port: Full Bore Ball Valve (ID is remains the same size as the pipe size)

- ● Handle: Blow-Out Proof

- ● Handle Locking Mechanism: handle equiped with locking device (Re-movable)

Performance Specifications:● Pressure Rating: 1000 PSI (6.4MPa) Making them suitable for most applications.

●Temperature: -13⁰F to 302⁰F (-25°C to 150°C)

● Shell Test: 9.6MPa

● Seat Test: 0.6MPa

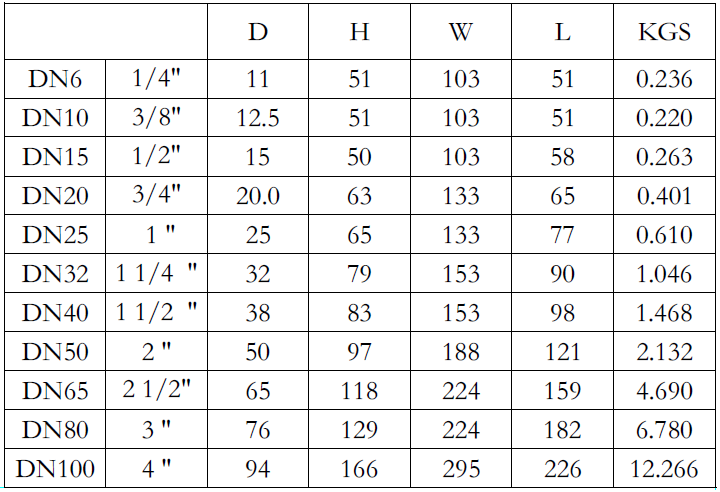

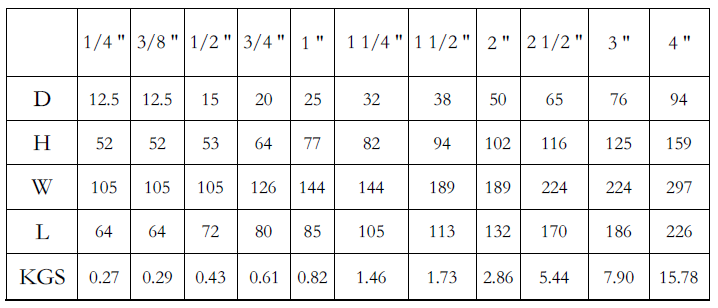

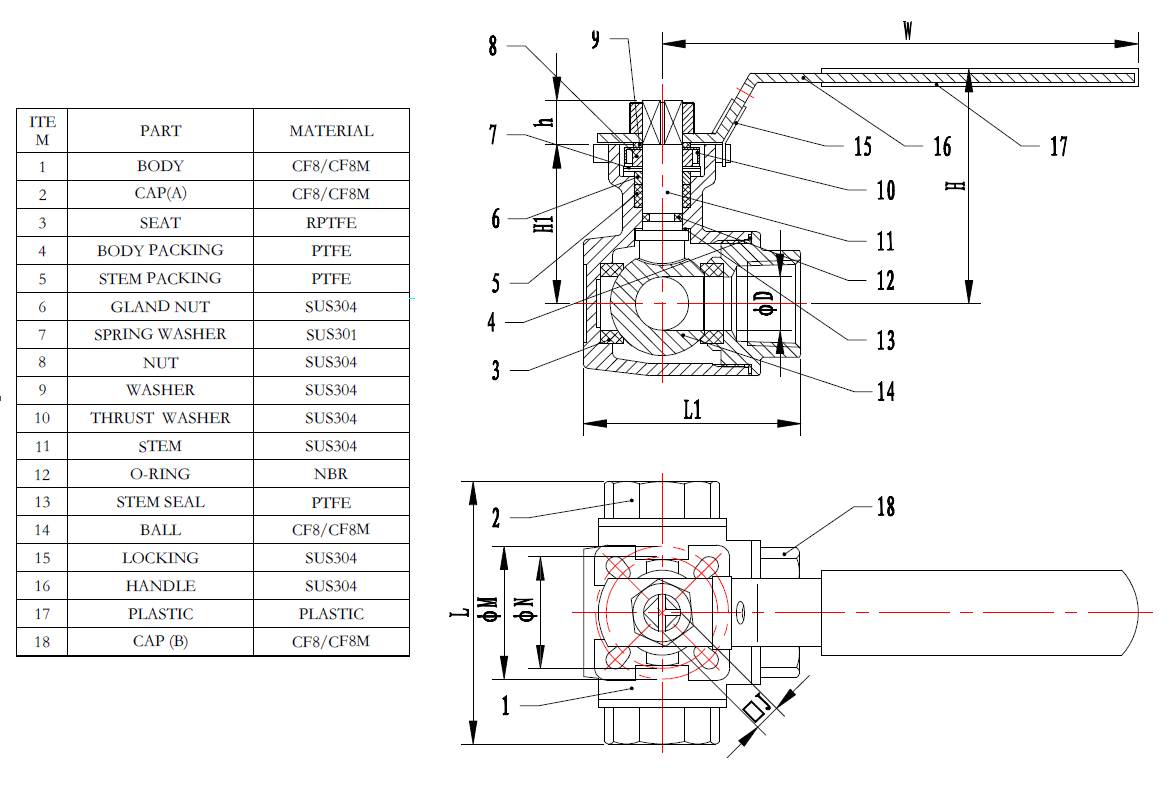

General Characteristics:

- ● The destinctive feature of this valve is that it can be easily taken apart for cleaning.

- ● By loosening 4 bolts the body separates into three parts.

- ● This allows one to leave the ball valve threaded in its current application while just removing the ball valve portion.

- ● Widely used in the food and beverage industry and other applications where cleaning is required.

Material components:

- ● Valve Body: Manufactured out of Staineless Steel 316 (CF8M)

- ● Seats & Seals: Composed out of Teflon (PTFE)

- ● Compatability: Compatible with any substance suitable to be used with Stainless Steel and PTFE

- ● All parts of the valve that touch the medium being moved are Stainless steel (316) and Teflon (PTFE)

General Dimensions:

- ● The body of this valve is divided into 3 segments held together by nuts, bolts and pipe nipples.

- ● Two sections have threads and the center portion contains the ball valve.

- ● The Center portion can be removed, leaving the other two ends still connect to the pipe for easy access without having to unscrew the whole ball valve.

● Pressure Chart:

Design Data:

- ● Design & Manufacture According To: EN12516-1/-2,PED97/23/EC (CE0036)

- ● Dimension standards To: DIN3202/4-M3,din2999/259 ,ISO228-1,ISO7-1,ASME B1.20.1,BS21

- ● Casting According To: AD2000-WO

- ● Valve Inspection & Testing According To: En12266-1,API 598;

- - Shell test pressure : 95 bar for DN6~DN50;60bar for DN65~DN100

- - Seal Pressure Test: 70 bar for DN6-~DN50; 44bar for DN65~DN100

- - Low Pressure Test : 6~8 bar

- ● Suitable Mediums: Water, Oil and Gas (WOG)

- ● Temperature Range: -14°F to 248°F (-10℃ ~ 120℃)

- ● Pressure at max. Temperature:44.5 bar for 1.4308 and pn63,50.2bar for 144.8 adn PN63; 28.2 bar for 1.4308 and PN40,31.8 bar for 1.4408 and PN40

- ● Pressure at min. Temperature: 59.7 bar for 1.4308 and PN63, 61.2 BAR FOR 1.4408 and PN63; 37.9 bar for1.4308 and PN40,38.8 bar for 1.4408 and PN40

- ● Corrosive Allowance : 2mm

- ● CE Approval for: DN32~DN100.

Click Here for the 3 Piece Stainless Steel Ball Valves Page

Features:

- ● Suitable Mediums: Water, Oil and Gas. (WOG)

- ● Seats and Seals: Teflon (PTFE)

- ● Threads: Female NPT (National Pipe Thread)

- ● Standard Port: Reduced Bore Ball Valve

- ● Handle: Blow-Out Proof

- ● Handle Locking Mechanism: handle equiped with locking device (Re-movable)

Performance Specifications:● Pressure Rating: 1000 PSI (6.4MPa) Making them suitable for most applications.

●Temperature: -13⁰F to 302⁰F (-25°C to 150°C)

General Characteristics:

- ● 3 Way Ball Valves come in two styles depending on the flow pattern they produce namely the L-Port and the T-Port.

- ● The L-Port valve produces flow in a L-Shape and are used as Diverter Valves, diverting flow from one inlet to a choice of two outlets.

- ● They may also be used as Selector Valves, choosing between one of two inlets to flow to a given outlet.

- ● The T-Port produces flow in a T-Shape and are used as Mixing Valves blending flow from two inlets.

Material components:

- ● Valve Body: Made out of Stainless Steel 316 (CF8M).

- ● Seals and Seats: The Seals are made out of Telflon also called PTFE.

- ● Compatability: Suitable for substances that are compatible with both Stainless Steel and Teflon (PTFE).

- ● All the parts touching the product being transported, are manufactuerd form long lasting Stainless Steel 316, the non-wetted parts are stainless Steel 304.

General Dimensions:

- ● Although these are made from four pieces, namely a valve body with three caps attached to each port end, the body is still made out of one piece.

- ● This means that they cannot accept a ball as large as the 2 Piece & 3 Piece can.

- ● This makes their ID (internal diameter) smaller than the full port, however they are not as reduced as the standard port or reduced port.

- ● The ID is wider than the one piece ball valve of equivalent size.

● Pressure Chart:

Click Here for the 3 Way Stainless Steel Ball Valves Page

2000 PSI Ball Valve:

Features:

- ● Mediums: Water, Oil & Gas. (WOG)

- ● Seats & Seals: Teflon (PTFE)

- ● Threads: Female NPT (National Pipe Thread)

- ● Full Port: Full Port Ball Valve

- ● Handle: Blow-Out Proof

- ● Handle Locking Mechanism: handle equiped with locking device (Re-movable)

Performance Specifications:● Pressure Rating: 2000 PSI

●Temperature: -13⁰F to 302⁰F (-25°C to 150°C)

● Shell Test: 20MPa

● Seat Test: 0.6~0.8Mpa

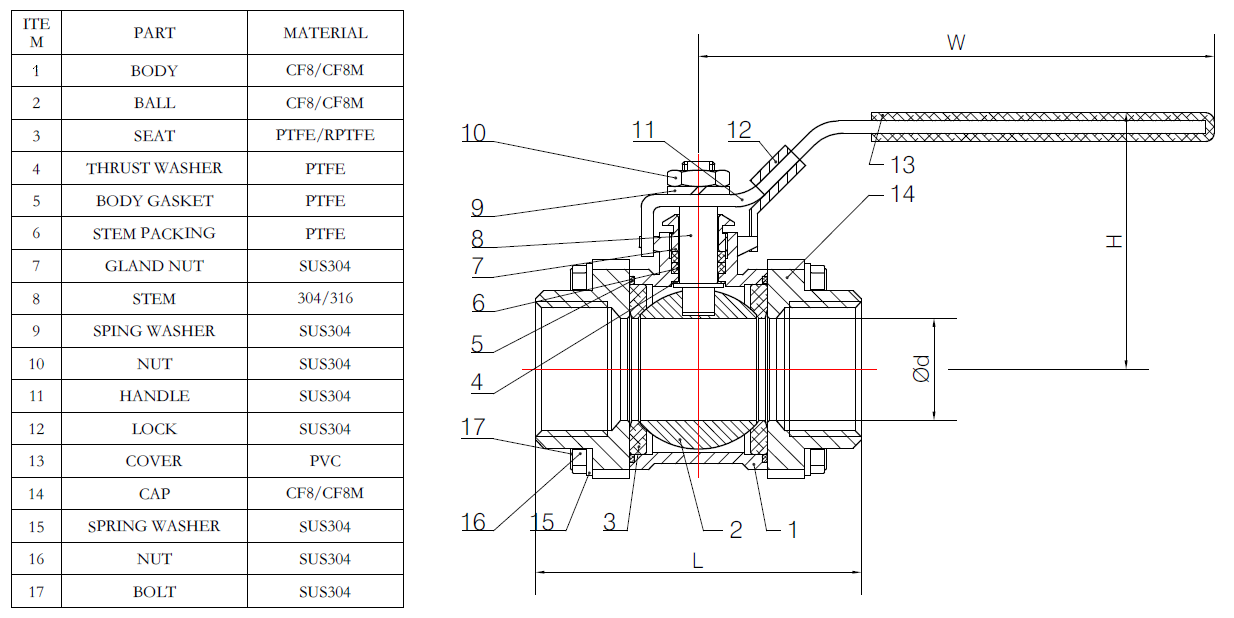

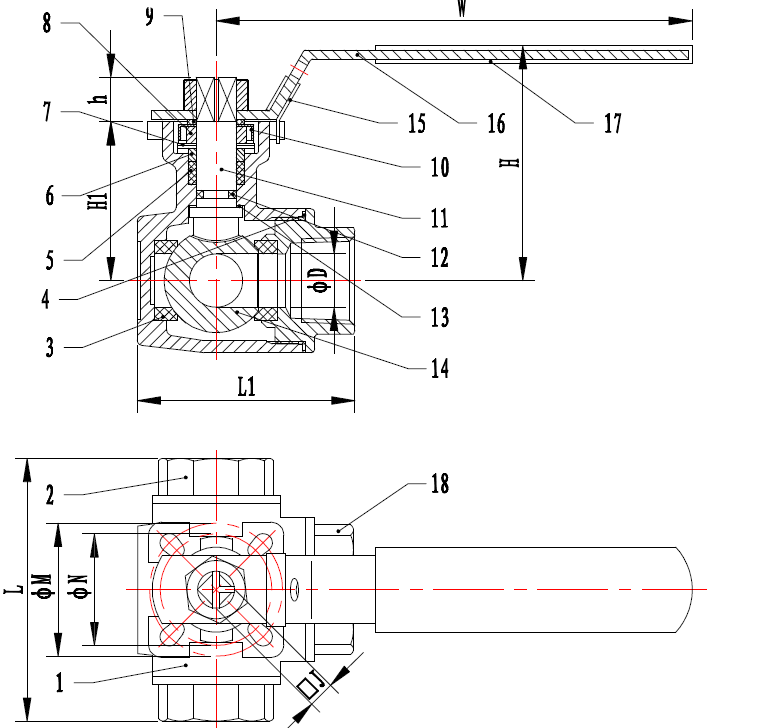

General Characteristics:

- ● Designed for high pressure applications, these valves have double the pressure rating than our standard offerings.

- ● The Valve Body is Heavier, longer and more robust than other 2-Piece ball valves.

- ● Although these valves are over-qualified, they can be used in everyday applications in place of the standard options.

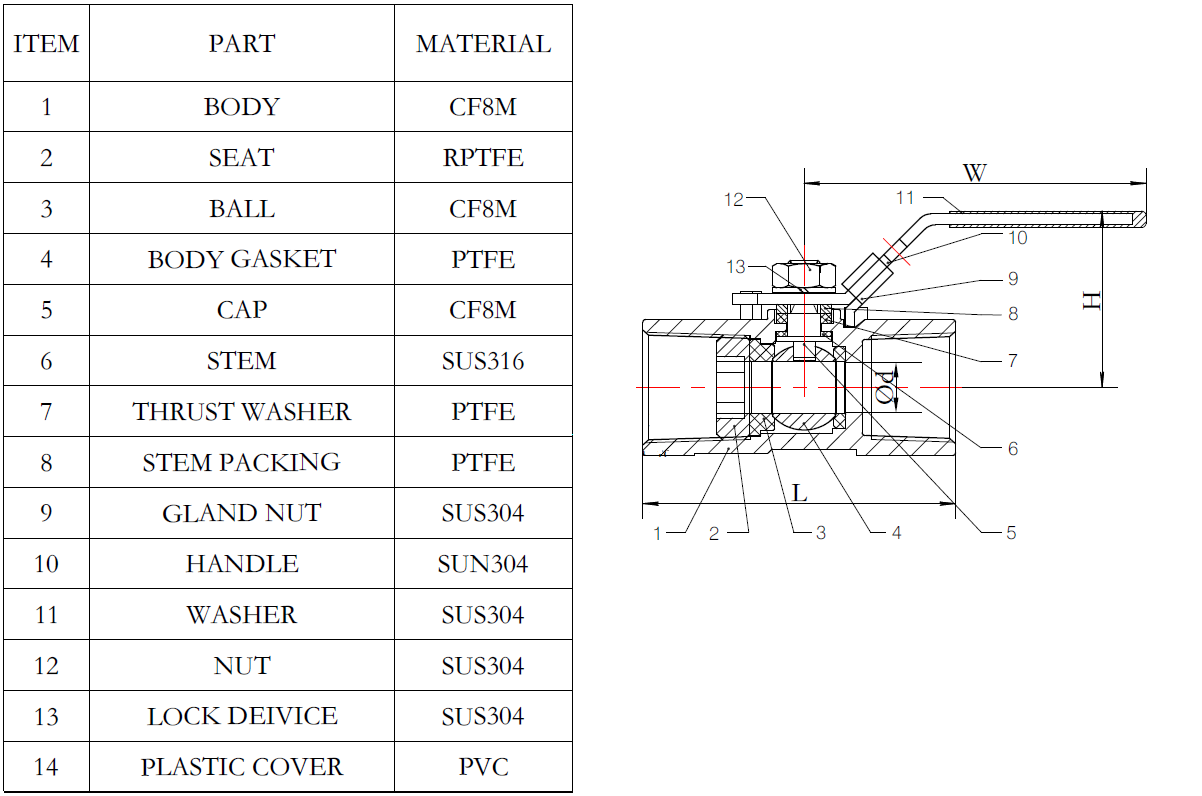

Material List Chart:

- ● Valve Body: Stainless Steel 316 (CF8M)

- ● Seats and Seals: The Seal Seat is composed of Teflon (PTFE) which makes this Robust Valve corrosion resistant,Heat & Chemical resistant.

- ● Compatibility: Suitable to be used with any substance compatible with Stainless Steel and Teflon (PTFE).

- ● All wetted parts of the valve that touch the product being transferred are PTFE (Teflon) and 316 Stainless steel (CF8M).

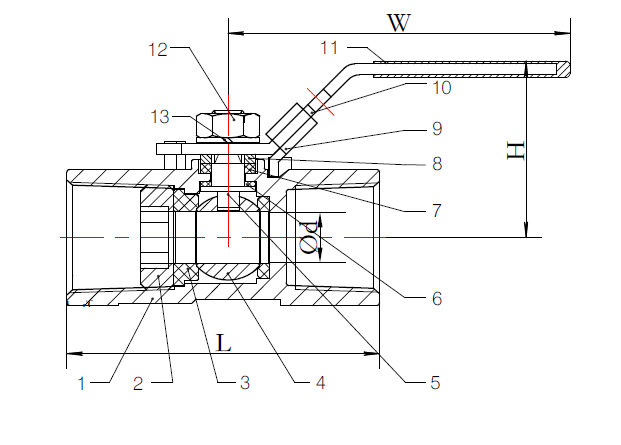

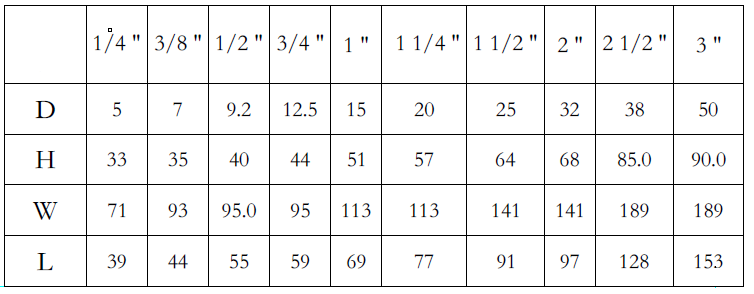

● General Dimensions:

- ● The valve body is heavier, longer and more robust that the standard 2 piece Ball valve.

- ● The size of the thread determines the size of the ball valve needed. (A 3" Thread will need a 3" ball valve and so forth.)

- ● These threaded ball valves don't require any tools to install. (The Female NPT Thread of the valve will screw directly onto a Male NPT Thread)

Design Data:

- ● Design Standard: ASME B16.34

- ● Nominal Diameter: DN8-DN50(1/4”~2”)

- ● End Connections: DIN259/2999、ISO228/1&ISO7/1

- ● Threads: ASME B1.20.1、BS21

- ● Inspection & Testing: According to API 598, EN12266-1

Click Here for the 2000 PSI Stainless Steel Ball Valve Page